Leading Industries That Rely on Epoxy Injection Molding

The Influence of Epoxy Injection Molding: Revealing Its Advantages and Versatile Applications

You may be shocked by exactly how epoxy injection molding is changing various industries. This process isn't simply concerning developing light-weight and solid components; it's additionally regarding efficiency and sustainability. As you discover its applications in fields like vehicle and aerospace, you'll discover intriguing benefits that can change how products are made and manufactured. What happens if these innovations could redefine industry standards? Let's uncover the possible together.

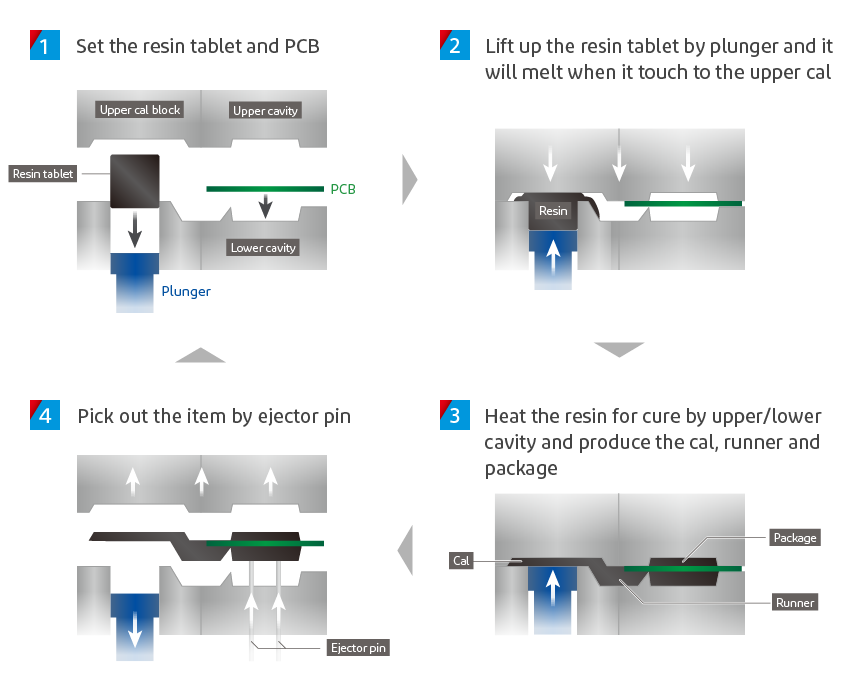

Understanding Epoxy Shot Molding

When you take into consideration modern production techniques, epoxy shot molding stands out as a effective and flexible process - epoxy injection molding. This method entails injecting liquid epoxy material right into a mold, where it solidifies into a sturdy element. You'll value exactly how it combines the advantages of traditional injection molding with the unique buildings of epoxy.Epoxy resins, recognized for their extraordinary attachment and stamina, permit the development of intricate designs with outstanding surface coatings. As you check out the procedure, you'll understand it's ideal for creating both little and big amounts of parts, making it cost-efficient for various applications.Understanding just how epoxy injection molding works can improve your decision-making in product growth. Whether you're working with automobile parts, electronic devices, or durable goods, you'll discover that this strategy meets varied production needs while making sure premium results. Embracing epoxy injection molding can really raise your manufacturing capacities

Advantages of Epoxy Resins in Manufacturing

You're choosing for remarkable toughness and toughness that can stand up to challenging problems when you select epoxy resins for manufacturing. Their outstanding chemical resistance indicates your items will certainly stand up against various compounds without wearing away. Plus, their functional application array permits you to utilize them in a wide range of markets, making them a wise choice for your tasks.

Superior Longevity and Stamina

Epoxy resins are recognized for their remarkable resilience and toughness, making them a top choice in producing processes. When you select epoxy, you're choosing products that can stand up to high tension and pressure, making sure lasting performance. This resilience indicates that components made from epoxy can endure rough environments without breaking or breaking. You'll also discover that epoxy's strength-to-weight ratio goes over, permitting light-weight styles without compromising structural stability. This is particularly beneficial in sectors like automobile and aerospace, where every ounce counts. By incorporating epoxy into your production, you improve the durability and reliability of your products, decreasing the need for constant replacements and upkeep. Ultimately, this selection causes more efficient and cost-efficient procedures.

Exceptional Chemical Resistance

Among the standout functions of epoxy materials is their superb chemical resistance, which makes them excellent for numerous manufacturing applications. You'll locate that these resins endure harsh chemicals, solvents, and acids without degrading, making sure resilient performance popular environments. This toughness indicates you can utilize epoxy in industries such as automobile, aerospace, and electronic devices, where direct exposure to harsh compounds prevails. You will not have to stress about premature failure or frequent substitutes, which can save you time and money. Plus, the capability to keep architectural stability under chemical anxiety makes epoxy a trusted option for protective finishes and adhesives. With epoxy, you're selecting a product that can handle the toughest challenges easily.

Functional Application Array

Past their amazing chemical resistance, epoxy materials supply a functional application variety that deals with various industries. You'll locate these resins in automobile elements, electronic devices, and building and construction materials, demonstrating their adaptability. In the auto field, they're made use of for light-weight parts that enhance fuel effectiveness. In electronics, epoxy offers as an excellent insulator, protecting delicate elements from moisture and damages. The construction industry take advantage of their use in finishes and adhesives, supplying toughness and resistance to extreme conditions. Additionally, developers and artists use epoxy for creating spectacular coatings in furniture and art work. With such varied applications, it's clear that epoxy resins not just satisfy various manufacturing needs yet also improve item efficiency throughout the board.

Applications in the Automotive Industry

Lightweight elements and boosted sturdiness are essential for performance when you assume about the vehicle industry. Epoxy shot molding plays an essential duty in manufacturing these components, supplying a solid yet light-weight option. By leveraging this technology, you can substantially boost car effectiveness and long life.

Light-weight Component Manufacturing

Lightweight component manufacturing is transforming the automobile sector by boosting gas performance and efficiency. By utilizing epoxy shot molding, you can develop parts that are not only lighter but additionally preserve structural integrity. These components help lower the general weight of automobiles, bring about reduced gas consumption and decreased emissions. You'll find that lighter lorries can accelerate faster and deal with much better, enhancing the driving experience. In addition, this approach enables more design flexibility, permitting for cutting-edge shapes and arrangements that conventional materials can't attain. As manufacturers accept these lightweight solutions, you're most likely to see a shift in vehicle design, prioritizing efficiency without sacrificing top quality. Inevitably, light-weight production is setting a new requirement for auto quality.

Improved Durability Functions

As auto suppliers increasingly transform to epoxy injection molding, they're uncovering considerable improvements in the longevity of their components. This procedure creates components that stand up to severe temperatures, moisture, and chemicals, guaranteeing they can withstand severe driving problems. You'll discover that these durable components not just enhance the life-span of automobiles yet additionally minimize maintenance costs for customers. Epoxy shot molding supplies superb impact resistance, shielding crucial parts from damages during accidents or harsh terrain. In addition, the lightweight nature of these components helps enhance gas efficiency without endangering toughness. By adopting this ingenious strategy, makers are able to provide more secure and more trustworthy vehicles, improving total client contentment and strengthening their competitive edge in the automotive sector.

Usage Instances in Aerospace and Protection

Given the i thought about this strict requirements of the aerospace and protection sectors, epoxy injection molding shows important for creating components that stand up to severe conditions. You'll locate this technology is essential in generating light-weight yet sturdy parts, such as structural elements in aircraft and armed forces vehicles. The ability to mold and mildew facility shapes permits cutting-edge layouts that improve aerodynamic effectiveness and lower weight without endangering strength.Moreover, epoxy injection molding's resistance to severe chemicals and temperature fluctuations discover this makes it excellent for mission-critical applications. You might encounter it in the manufacturing of gas tanks, insulation systems, and protective housings for sensitive instruments.Additionally, this procedure enables rapid prototyping, allowing developers to quickly iterate and evaluate new principles. By leveraging epoxy injection molding, you ensure that your aerospace and protection projects fulfill extensive requirements while profiting from economical manufacturing techniques. Accepting this modern technology can significantly improve your capabilities in these demanding markets.

Epoxy Injection Molding in Electronic Devices

While the need for miniaturization and effectiveness in electronic devices remains to expand, epoxy injection molding stands out as a crucial manufacturing process. This technique allows you to generate detailed parts with high precision, making sure that also the tiniest electronic devices keep peak capability. With its superb thermal security and electric shielding residential or commercial properties, epoxy is perfect for enveloping sensitive electronic devices, securing them from moisture, dirt, and mechanical stress.Using epoxy injection molding, you can achieve intricate geometries that typical techniques battle with, boosting style flexibility. The capability to create light-weight yet sturdy parts helps in reducing overall gadget weight without giving up efficiency. Plus, this technique often causes reduced production expenses as a result of its efficiency and decreased waste - epoxy injection molding.As you explore choices for your digital applications, consider how epoxy injection molding might simplify your production process and boost the quality of your products. It's a game-changer for the advancing electronic devices sector

Effect On Industrial Equipment and Machinery

Epoxy shot molding verifies to be an essential procedure that boosts resilience and performance when you consider the demands of industrial equipment and machinery. This technique enables you to produce elements that withstand severe problems, consisting of heats, chemicals, and mechanical stress and anxiety. By utilizing epoxy material, you're ensuring that the parts preserve their stability longer, decreasing the demand for constant replacements.Moreover, epoxy shot molding allows accurate production of intricate forms, which is essential in enhancing the capability of machinery. You'll find that the exceptional adhesion buildings of epoxy improve the general stamina of constructed elements, even more boosting reliability.In addition, the lightweight nature of epoxy products contributes to energy efficiency in machinery procedure. By selecting epoxy injection molding, you're go to this web-site investing in a process that not just satisfies the rigorous needs of sector however also sustains sustainability with decreased waste and extensive devices life expectancies.

Future Fads and Innovations in Epoxy Injection Molding

As the market evolves, you're likely to see exciting fads and advancements in epoxy injection molding that press the borders of what's possible. One significant fad is the assimilation of wise technology, enabling real-time tracking and top quality control during the molding procedure. This means you can accomplish higher accuracy and decrease waste considerably.Additionally, developments in environmentally friendly epoxy formulations are arising, making the process a lot more sustainable without jeopardizing performance. You're also likely to come across improved automation methods, which improve manufacturing and enhance effectiveness, reducing lead times.Moreover, as sectors demand lighter and stronger materials, epoxy compounds are being customized for certain applications, such as aerospace and auto industries. With these innovations, you're not simply maintaining pace with the market; you're positioning yourself at the leading edge of a swiftly progressing area, ready to leverage new possibilities and supply exceptional products.

Often Asked Questions

Just How Does Epoxy Shot Molding Compare to Conventional Molding Methods?

Epoxy injection molding supplies far better precision and longevity compared to standard methods. You'll see enhanced stamina and lowered waste, making it a more effective option for complicated styles and high-performance applications in numerous industries.

What Precaution Are Required When Making Use Of Epoxy Resins?

When using epoxy resins, you ought to use protective handwear covers, safety glasses, and a mask. Ascertain proper ventilation and stay clear of skin call. Constantly review security information sheets to comprehend the certain dangers related to your materials.

Can Epoxy Be Recycled After Injection Molding?

You can't usually recycle epoxy after shot molding as a result of its chemical framework. When cured, it ends up being a thermoset polymer, making it hard to recycle. Nevertheless, some advancements in recycling approaches are arising.

What Are the Typical Difficulties in Epoxy Injection Molding?

You'll typically deal with obstacles like accomplishing proper curing, taking care of thickness, and protecting against air bubbles throughout epoxy shot molding. epoxy injection molding. Obtaining the ideal temperature and pressure is necessary, as well, to ensure a constant and successful molding process

How Does Temperature Level Affect Epoxy Treating During Shot Molding?

Temperature substantially affects epoxy healing during shot molding. Higher temperature levels accelerate the healing process, while lower temperatures can slow it down or lead to insufficient curing, affecting the final item's stamina and longevity. With its outstanding thermal security and electrical insulating residential properties, epoxy is excellent for encapsulating delicate electronics, shielding them from dampness, dust, and mechanical stress.Using epoxy shot molding, you can accomplish intricate geometries that typical approaches struggle with, boosting design versatility. Plus, this method usually results in lower production costs due to its effectiveness and reduced waste.As you discover options for your electronic applications, consider just how epoxy shot molding could enhance your manufacturing procedure and enhance the high quality of your items. When you think about the demands of industrial devices and equipment, epoxy shot molding confirms to be a crucial procedure that boosts resilience and efficiency. By using epoxy material, you're guaranteeing that the parts maintain their integrity much longer, reducing the need for frequent replacements.Moreover, epoxy injection molding enables exact production of intricate forms, which is vital in enhancing the capability of equipment. You'll locate that the remarkable attachment residential or commercial properties of epoxy boost the overall stamina of set up parts, better increasing reliability.In enhancement, the lightweight nature of epoxy materials contributes to energy performance in equipment procedure.